Photovoltaic Cells: Solar Energy Conversion using Semiconductors

Energy harvesting is the most environmentally friendly way to ensure electronic devices remain powered. Various hints and guidelines help achieve maximum efficiency when using solar cells or photovoltaic cells. This article starts by looking at the Electronic Engineering fundamentals of solar-cell exploitation and then moves on to a quick study of recent advances leading to higher efficiency.

Power Matching Yields optimal efficiency

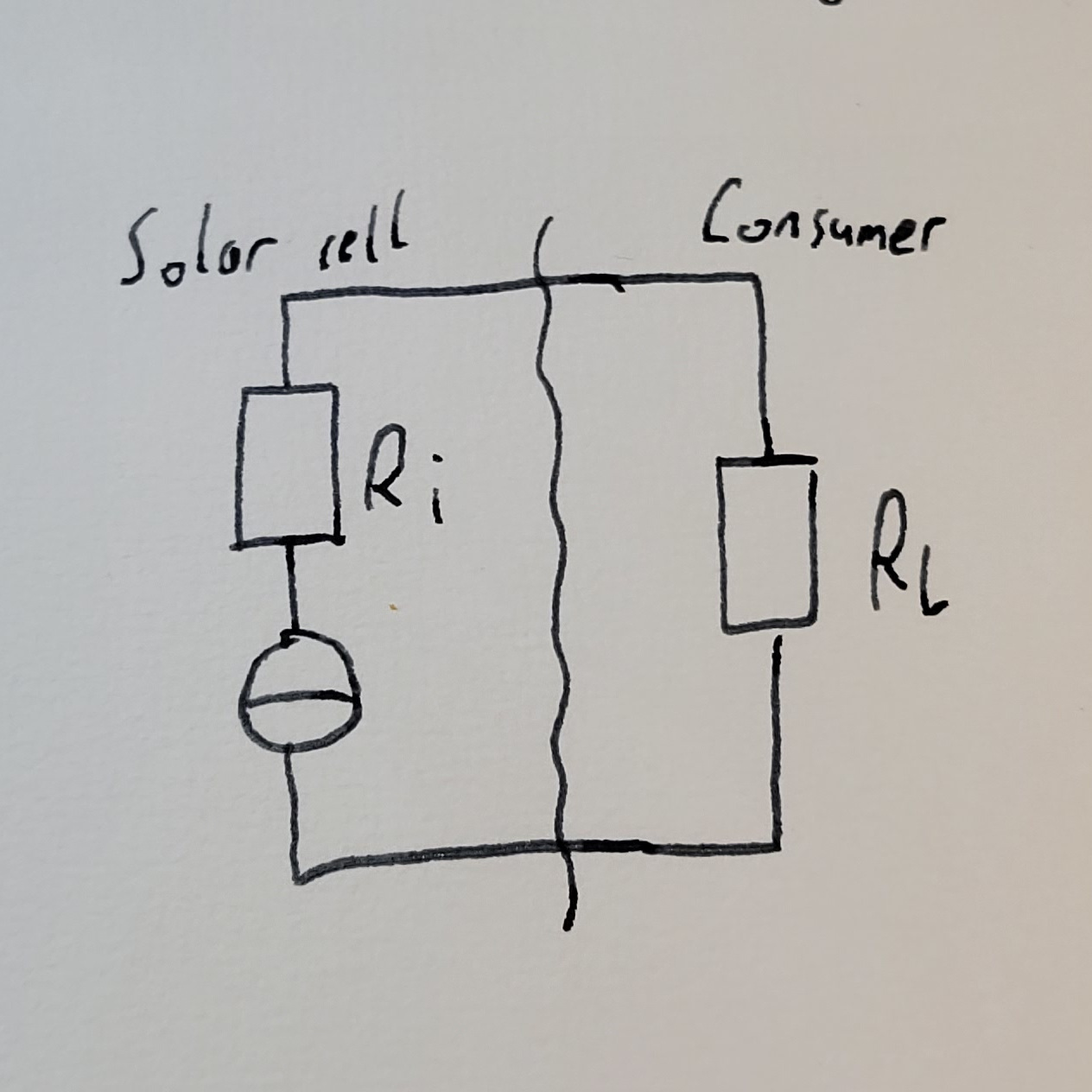

When working with solar cells, assuming ohmic behavior – by and large – is a safe bet. Given that every power source has an internal resistance, a two-element system like the one shown in the figure emerges.

Power matching is required if the goal is to extract the maximum amount of power from the source. Calculus concludes that this state is reached when the source and the load impedance are equal – changes to voltages and currents are part and parcel of the equation. In the case of a solar panel, the source impedance changes in relationship to incoming light quality; an adjustable load is required. This is best accomplished via a set of circuits known as Maximum Power Point trackers. If the assignment involves many solar cells (e.g., for the power grid), purchasing them as an off-the-shelf component is usually the most economically efficient way. For smaller systems, integrated circuits like the ones discussed below are an attractive choice.

Efficiency increases due to improved Semiconductor Technology and Topologies

Most thermodynamic machines are limited in their efficiency output by various laws of physics. A good example would be the Carnot process, which limits classic combustion engines. In the case of solar cells, the most common limit is the Shockley–Queisser limit, which postulates that a single PN gateway can reach a maximum efficiency of around 30%. Solar cells have, by and large, converged to about 27% as of 2023. Multi-junction cells work around this problem by combining multiple PN gateways in one cell. In laboratory settings, some of these have reached efficiencies far above the Shockley-Queisser limit; they are also available on the market. In practice, however, increased efficiency only sometimes translates to a lower total cost of ownership. Advanced cells such as the multi-pn-elements discussed above cost factors more than their slightly less efficient colleagues, limiting their use to cases such as aerospace where weight is at a premium.

Energy Harvesting via Integrated Circuits

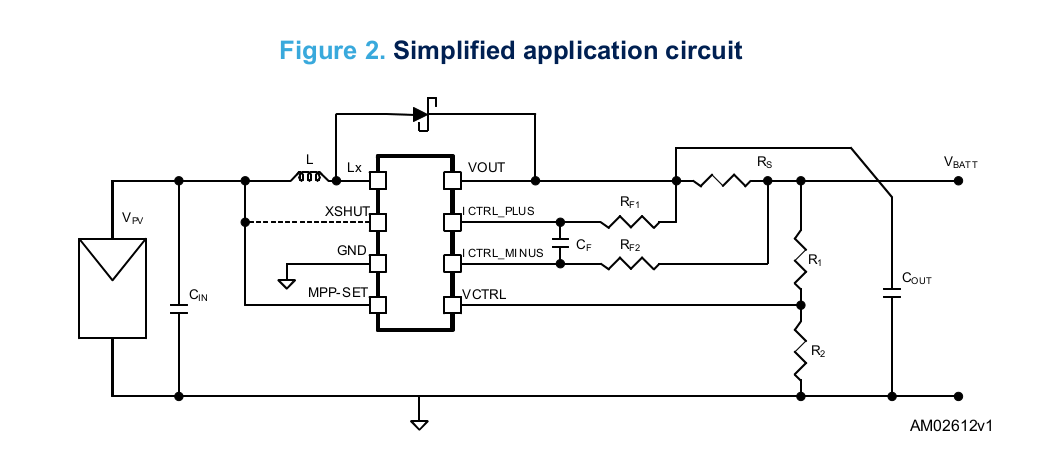

When working on medium-scale (as in residential or small business) energy-generation applications, using a premanufactured Maximum Power Point Tracker, or MPPT for short, is usually the most economical. On the other hand, ready-made integrated circuits are available for energy harvesting. A good example is STMicroelectronics SPV1050 range, which combines the energy harvesting logic with a low dropout regulator onto a single semiconductor die. This leads to simple schematics such as the one shown in the figure.

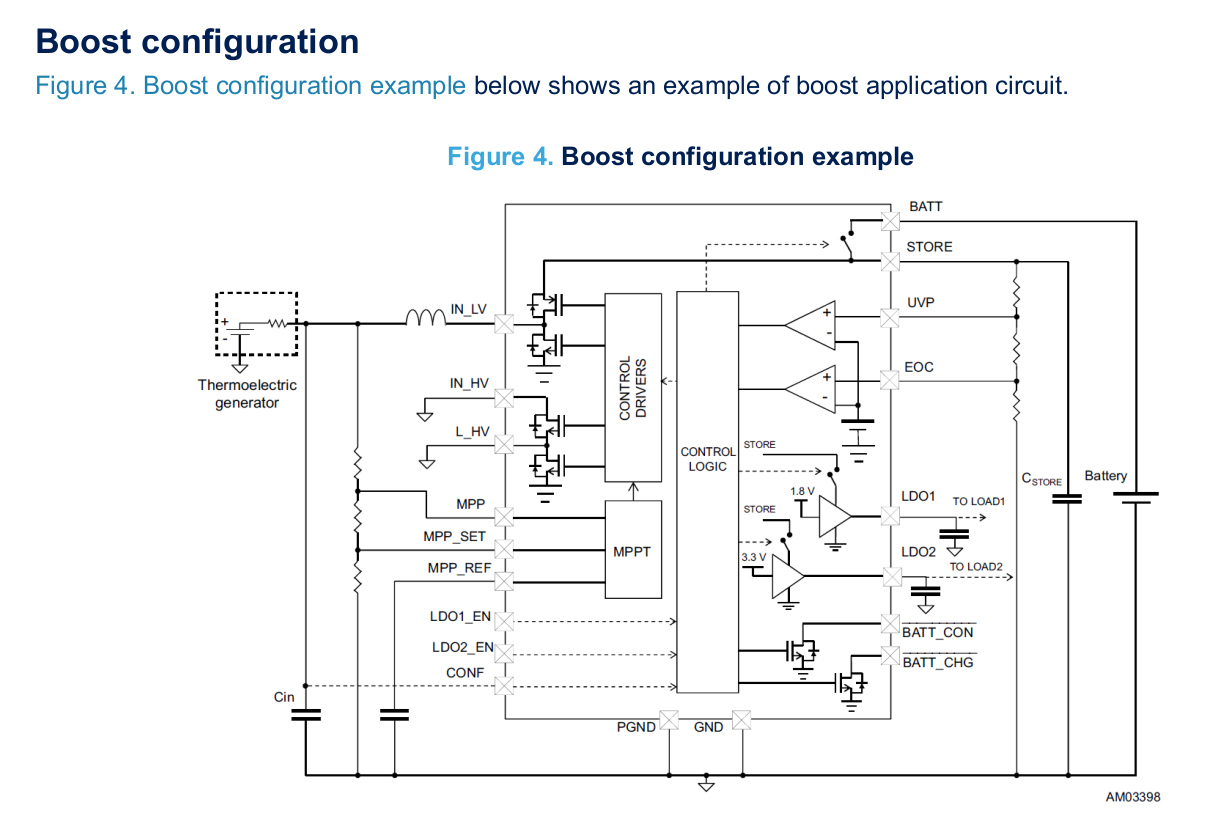

Such “all in one” solutions are available from multiple semiconductor vendors and – usually – provide output currents of up to 100 mA due to thermal limits on the small semiconductor dies. Higher current charging can be accomplished at the expense of lower integration. An example is the SPV1040, which uses schematics similar to the ones shown in the figure.

Issues Related to Polar Panel Usage

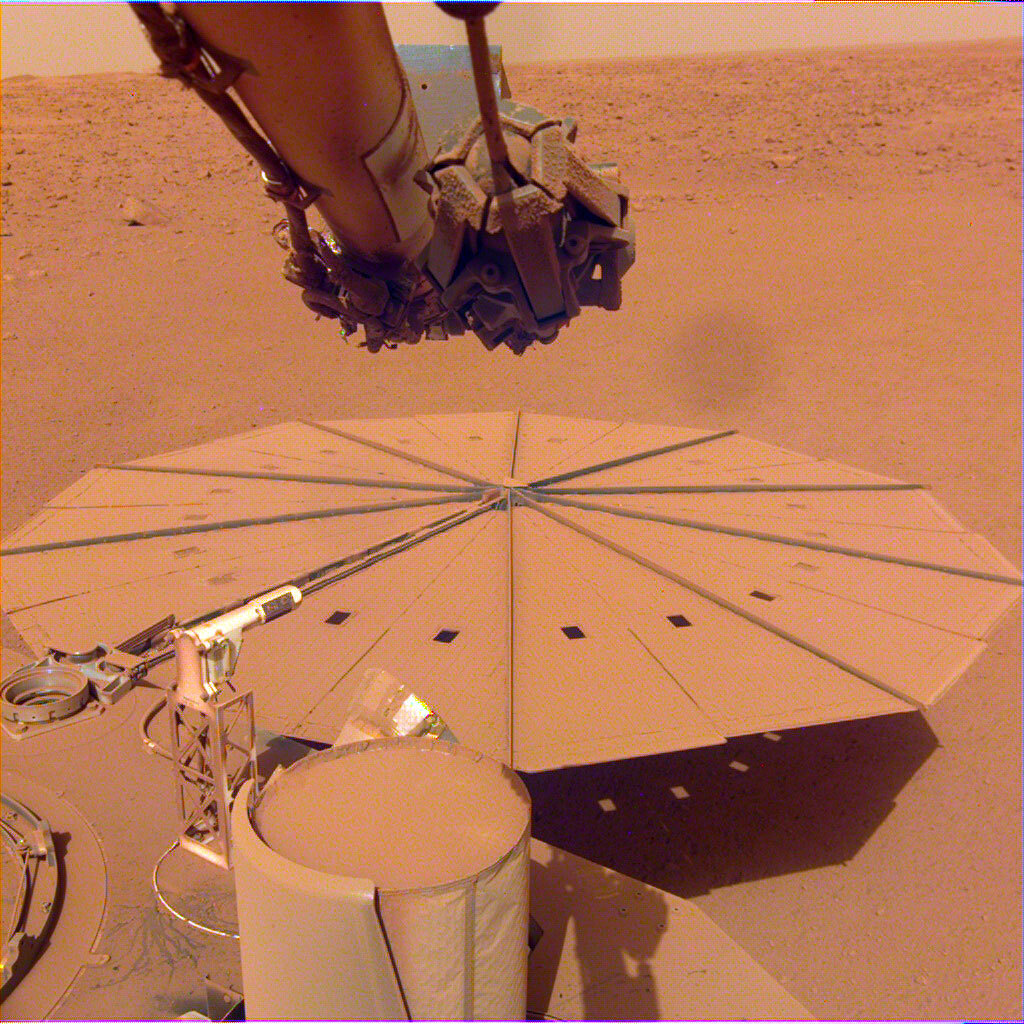

When using solar panels in practical application, take care to avoid soiling of the panel surface. A classic example is the Insight Mars rover, which lost power due to excessive dust settling on its solar panels.

This issue also occurs on Earth and must be considered if maintenance engineers will not easily reach the system in question. Research done on terrestrial solar panel applications has shown degradations ranging from 5 to 20% annually. On the other hand, aging is not a significant concern – high-quality panels age at a rate of less than 3% annually. The speed of aging can, of course, be reduced by thermal management – on the other hand, the highly variable availability of solar power output means that overprovisioning is recommended in almost all cases.