Ensuring Electrical Safety and System Reliability in Converters

This article discusses the concept of insulation coordination in electrical systems and its significance in ensuring electrical safety and system reliability. It explains the factors affecting insulation and emphasizes the growing demand for it.

The growing practicality of wide band gap power semiconductors, the widespread usage of distributed power generation, and the rise in power levels of various applications have all contributed to an increased interest in and demand for medium voltage converters.

What is the Significance of Insulation Coordination, and Why is it Important?

Electrical safety standards specify how electrical devices should be tested and operated in order to avoid potentially harmful conditions, including electrical current, electrical arcs, fire, electromagnetic fields, and static that might threaten people's lives and property.

The rules outlined in the standards are subject to continuous modification due to advancements in technology and shifting requirements. The major goals of insulation coordination are to maintain system operation continuity and safeguard the system against insulation failure while taking into account practical and financial considerations.

To put it briefly, the objective is to offer a system with minimal cost and dependable safety. System engineers are able to select the appropriate insulation materials for the design when they have a thorough understanding of the definitions of insulation coordination as well as their relationships to the applications and methodologies used in the testing environment.

This provides them with the ability to accurately calculate the required distances between the conductive surfaces, accessible parts, and ground.

Insulation Coordination

The process of defining the system's insulation levels by taking into account its voltage levels and figuring out the equipment's dielectric strength by taking into account the service environment and the features of the available protective devices is known as insulation coordination.

Factors Affecting Insulation Coordination

It is necessary to examine the system voltage stresses prior to conducting insulation coordination studies. The degree of pollution, the overvoltage category, the grounding type, the altitude, the kind of insulation, and the material type must also be taken into account.

Transmission lines, substations, power transformers, ultra-high DC voltage converter stations and transmission systems, wind turbines, and solid-state transformers are only a few of the systems for which a number of studies on insulation coordination have been carried out.

National and International Strandards

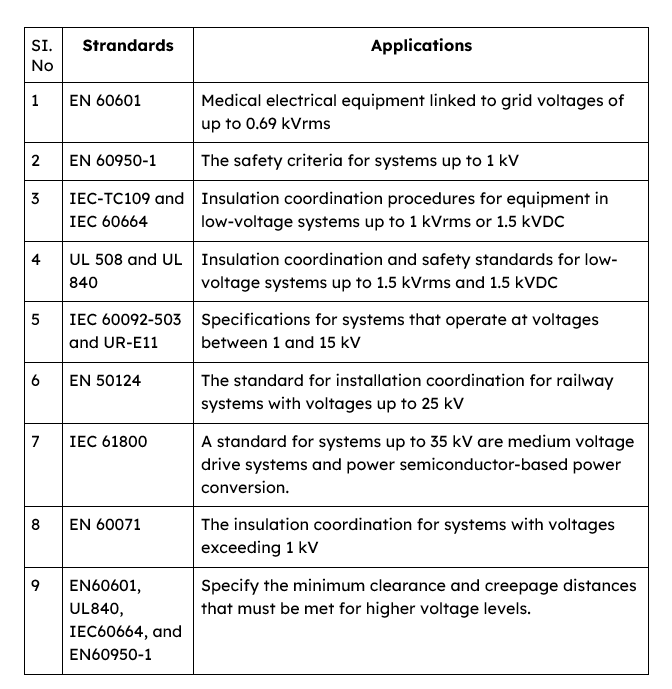

The requirements and a method for carrying out insulation coordination studies have been defined by a number of national and international standards; some examples are given in Table 1. For a variety of applications, these standards offer definitions and methods for testing and designing at various voltage levels.

Table 1. National and International Standards and their applications

It is obvious that standards specific to the operating voltage of a system should be followed; the majority of these standards address low-voltage systems. Furthermore, a few of them are suggested for particular uses, such as controlled speed drives, luminous indicators and discharge lamps, railway applications, medical electrical equipment, industrial control systems, and military and commercial marine applications.

It is also important to take into account the requirements unique to the application. Despite the fact that design standards have been thoroughly developed and implemented for low-voltage systems, there are still considerable gaps in both the understanding of and adherence to the insulation coordination requirements for medium-voltage and medium-frequency applications.

Evolution of Medium Voltage Power Electronic Converter

Applications utilizing power semiconductors connected directly to medium voltage (MV) have increased dramatically over the past 20 years. Among these are adjustable speed drives, Power Electronic Converter (PEC) interfaces to Distributed Energy Resources (DERs) and solid-state transformers that are used in particular application situations (such as shipboard DER interfaces) and as parts of power systems.

The development and commercialization of multilevel power converters, as well as the appearance of wide band gap (WBG) power semiconductors, have all contributed to this development.

Because of the size and cost penalties associated with meeting power quality requirements at the grid interface and the limitations in controllable performance, WBG power semiconductors are a necessary enabler for MV applications, where current Si devices impose a significant penalty on the achievable switching frequency.

Silicon carbide MOSFET power modules with voltages higher than 1.7 kV are becoming more common on the market. This will have a big impact on how MV PEC systems are used and implemented in the future. It is possible that modules with voltages up to 10 kV could also be used commercially.

MVDC Development

The development of MVDC applications has also attracted a lot of attention recently. Historically, low-frequency power components like transformers and switchgear have been used to test and validate the standards that apply to MV power systems. The MV PEC creates an electrical environment with varying frequencies, from dc to 50 kHz, on the system's internal components.

These issues happen a lot more often in MVDC-linked systems because they make the system less reliable by making up for things like line-to-ground voltage transients, DC-triggered surface flashover, and the polarization of surface pollutants.

Standards derived from substantial physics-based research in this field are still lacking, and it is obvious that new standards will develop along with considerable modifications to the current ones.

It seems sensible to use the current standards in the meantime, making thoughtful modifications to the nominal system voltage definitions that serve as the basis for creepage and clearance distance calculations. This strategy, meanwhile, might lead to cautious methods that enlarge the equipment.

Requirements of Insulation Design in Converters

There are two overall needs for insulation design that can be derived from the standards, as well as the enormous number of application notes. The requirements are as follows: (1) the safety of humans, and (2) the reliability with which equipment operates.

Both of these needs can be broken down into an extensive number of further considerations and sub-requirements, and they are both of equivalent significance.

One of the fundamental equipment safety requirements for PECs must be the abitility of independent isolation from equipment damage occurrences by the use of intervening protective equipment that is external to or otherwise distinct from the power electronic circuitry.

During maintenance and repairs, the PEC must guarantee that galvanic isolation has been achieved from electrical energization by the use of disconnect switches that are manually controlled, locked out, and tagged out. This is an essential component of the human safety requirement.

Insulation failures can be classified as either transitory (lasting only a few seconds), short-term (lasting from a few minutes to several hours), or long-term (lasting from several days to several weeks).

If the design of the insulation is focused on ensuring the operational reliability of the system, then any concerns about human safety during a serious malfunction of the insulation will be addressed, and suitable barriers will be installed in exposed areas of the system that would otherwise put human safety at risk.

Summarizing the Key Points

- Insulation coordination is a critical aspect of electrical design and testing that involves selecting appropriate protective devices and insulation materials to ensure electrical safety and system reliability.

- Factors affecting insulation coordination include system voltage stresses, pollution, overvoltage category, grounding type, altitude, insulation type, and material type.

- Insulation failures can be classified as transitory, short-term, or long-term, and suitable barriers must be installed in exposed areas of the system to address concerns about human safety during serious malfunctions.

- The growing practicality of wide band gap power semiconductors and the widespread usage of distributed power generation have increased the demand for insulation coordination.

- Proper insulation coordination can help prevent electrical accidents, reduce equipment damage, and improve system reliability, making it a crucial consideration in electrical design and testing.

Reference

Ozdemir, Saban, Necmi Altin, Adel Nasiri, and Robert Cuzner. “Review of Standards on Insulation Coordination for Medium Voltage Power Converters.” IEEE Open Journal of Power Electronics 2 (2021): 236–49. https://doi.org/10.1109/ojpel.2021.3065813.